规格型号代号:

Q SMC- V / X

其中:Q: 进水流量(m3/h);

SMC:新沃特脉冲布水器型式;

V:脉冲罐有效容积(m3);

X:(I-单路脉冲、II-双路脉冲、III-叁路脉冲、VI-四路脉冲、 V-五路脉冲);

备注:多路脉冲并联型式主要用于不规则池型。

设备简述

SMC型脉冲布水器是根据虹吸原理按不同进水量规模、通过优化设计而成,具有高效节能、运行可靠、满足各种复杂工况要求的优点。

设计良好的脉冲布水器能满足各类工艺水池对均匀布水、进水水力搅拌的要求。均匀布水或水力搅拌系统采用无故障设计,包括:即使发生意外堵塞情况下亦能快捷、方便的进行清堵。

脉冲布水器工作时,通过连续进水、间歇出水,在短时间内形成大大于平均流量的冲击流量,有利于厌氧(或水解或反硝化、或调节匀质)工艺池进水的均匀分布;实现污泥或进水快速混合;大幅度增加泥、水接触机率,及水力搅拌匀质的速度。使用脉冲布水器不需要任何控制和操作,不消耗额外能源,无易损部件。同时,在厌氧、水解生化处理中,通过间歇出水实现了反应器静置沉淀的效果,大大减少了污泥流失,提高了反应器生物量,降低了反应器出水悬浮物含量。

| 脉冲周期 (min) | ||||||||||||||||

| 1.5-2 | 2-3 | 3-4 | 4-5 | 5-6 | 6-7 | 7-8 | 8-9 | 9-10 | 10-11 | |||||||

| 3SMC-0.265/X | 3SMC-0.3/X | 3SMC-0.35/X | 3SMC-0.4/X | 3SMC-0.45/X | 3SMC-0.5/X | |||||||||||

| 5SMC-0.36/X | 5SMC-0.485/X | 5SMC-0.55/X | 5SMC-0.62/X | 5SMC-0.69/X | 5SMC-0.79/X | 5SMC-0.85/X | ||||||||||

| 10SMC-0.69/X | 10SMC-0.86/X | 10SMC-1.14/X | 10SMC-1.34/X | 10SMC-1.45/X | 10SMC-1.57/X | |||||||||||

| 15SMC-0.79/X | 15SMC-1.14/X | 15SMC-1.34/X | 15SMC-1.57/X | 15SMC-1.89/X | 15SMC-1.89/X | |||||||||||

| 20SMC-0.69/X | 20SMC-1.14/X | 20SMC-1.45/X | 20SMC-1.89/X | 20SMC-2.2/X | 20SMC-2.35/X | |||||||||||

| 30SMC-0.79/X | 30SMC-1.14/X | 30SMC-1.57/X | 30SMC-2.2/X | 30SMC-2.64/X | 30SMC-3.18/X | 30SMC-3.45/X | ||||||||||

| 40SMC-1.24/X | 40SMC-1.57/X | 40SMC-2.2/X | 40SMC-2.79/X | 40SMC-3.45/X | 40SMC-3.95/X | |||||||||||

| 50SMC-1.57/X | 50SMC-1.80/X | 50SMC-2.78/X | 50SMC-3.62/X | 50SMC-4.55/X | ||||||||||||

| 60SMC-1.80/X | 60SMC-2.35/X | 60SMC-3.3/X | 60SMC-4.75/X | 60SMC-5.35/X | ||||||||||||

| 70SMC-1.95/X | 70SMC-2.65/X | 70SMC-3.8/X | 70SMC-4.90/X | |||||||||||||

| 80SMC-2.24/X | 80SMC-3.0/X | 80SMC-5.1/X | ||||||||||||||

| 90SMC-2.4/X | 90SMC-3.14/X | 90SMC-5.5/X | ||||||||||||||

| 100SMC-2.5/X | 100SMC-3.25/X | 100SMC-6.15/X | ||||||||||||||

| 110SMC-3.14/X | 110SMC-4.15/X | |||||||||||||||

| X根据池型及容积合理选用I、II、III、IV型 | ||||||||||||||||

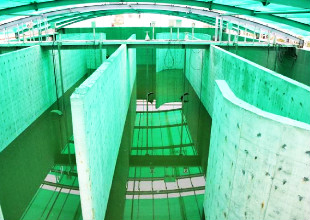

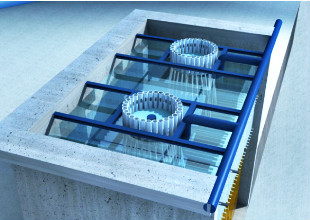

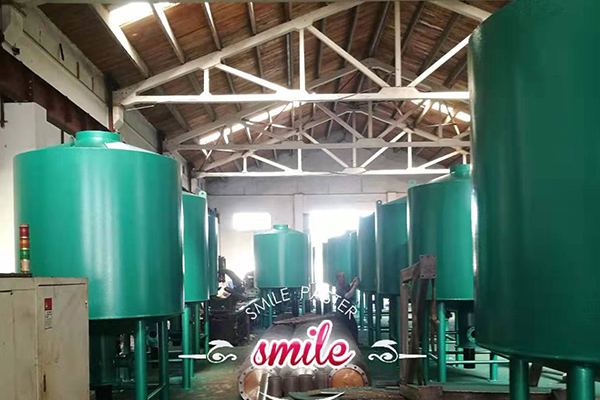

01 脉冲布水器展示图

02 脉冲布水器展示图

03 脉冲布水器展示图

04 脉冲布水器展示图

使用场景条件(厌氧、水解酸化、反硝化、调节匀质、生物滤池、或其它)

工艺设计规定参数(包括:进水量、工艺水池规格、脉冲布水器运行参数)

使用限制条件(包括:平面限制、高程限制、重量限制、材质限制)